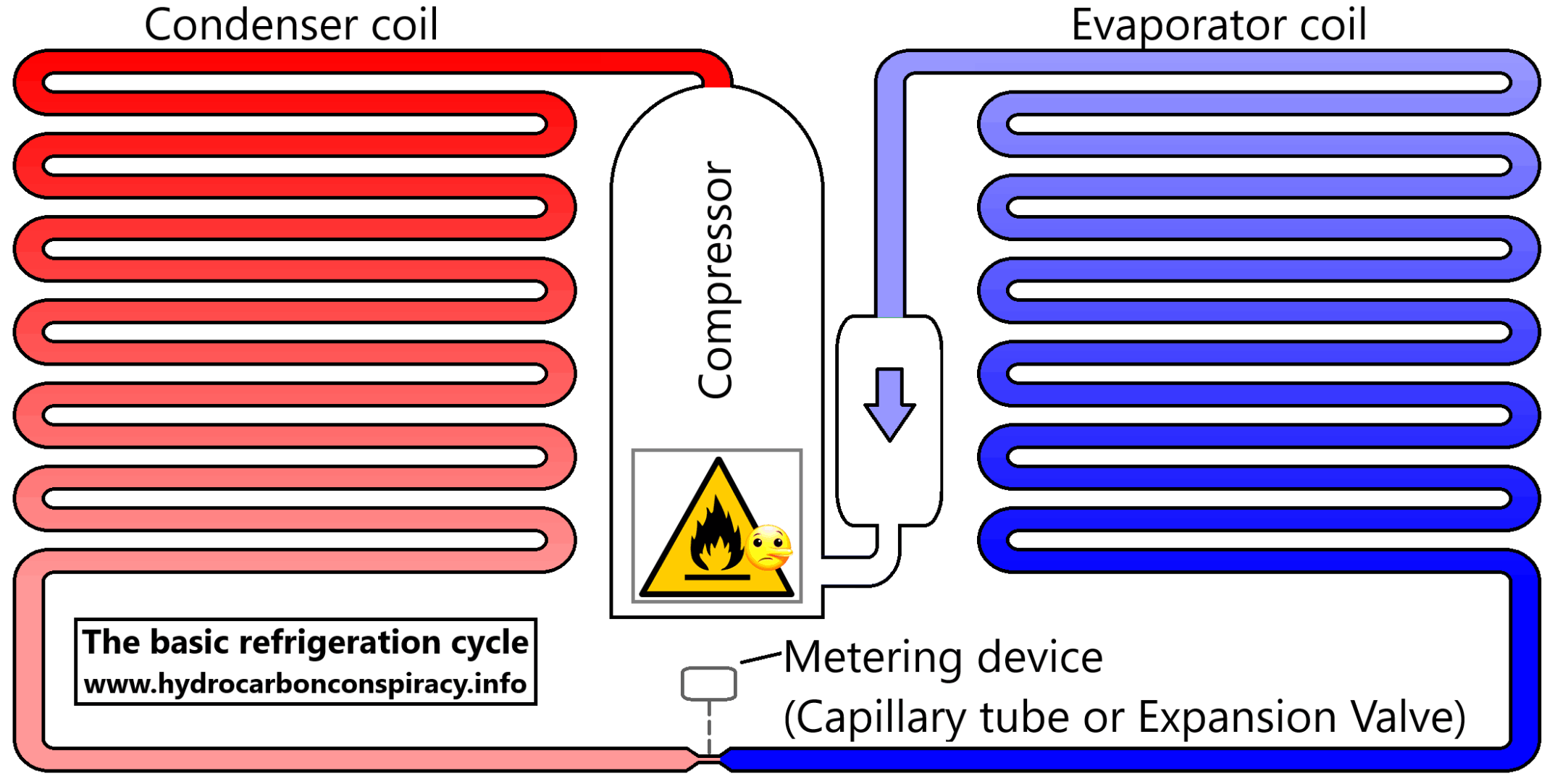

The basic refrigeration cycle

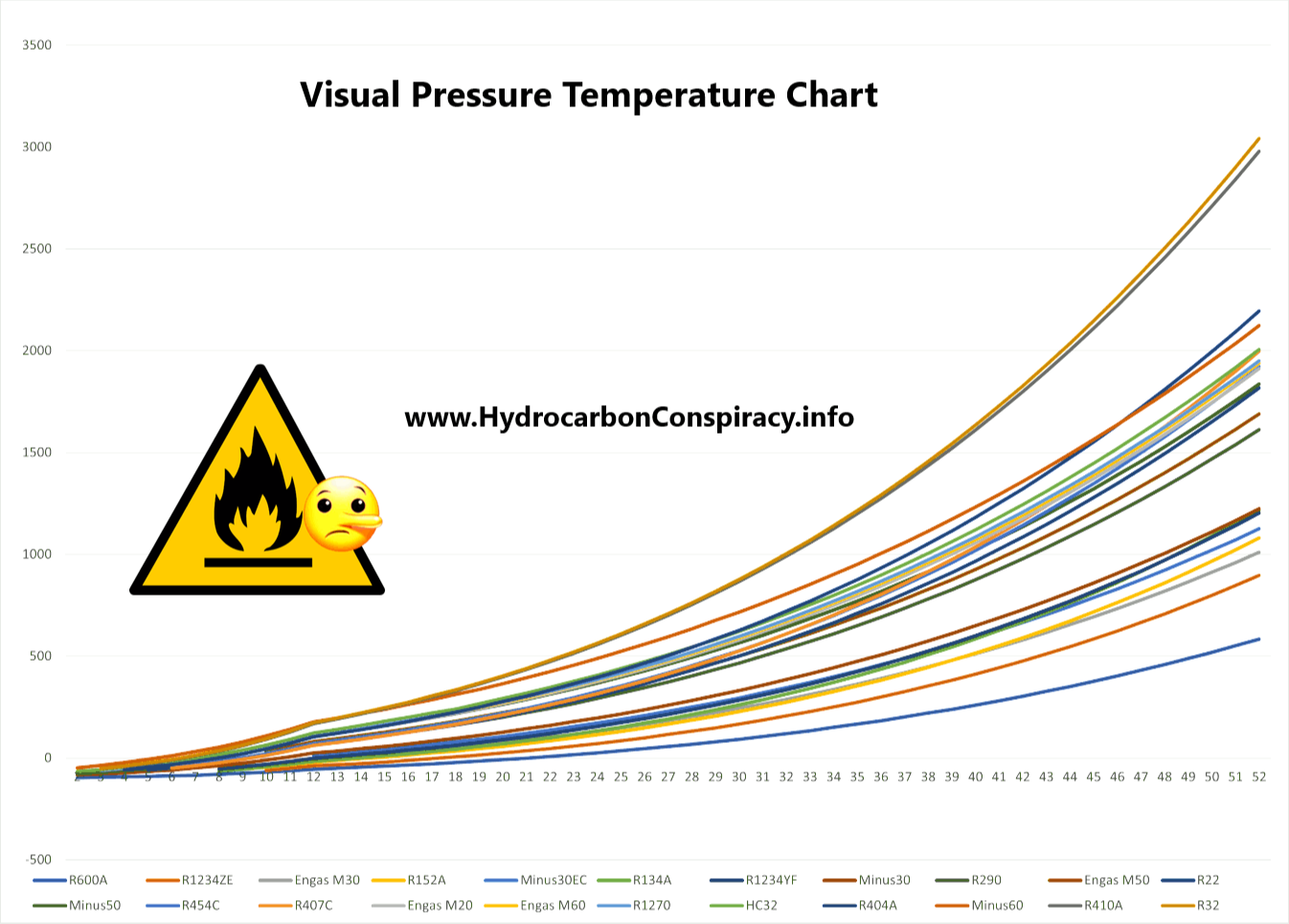

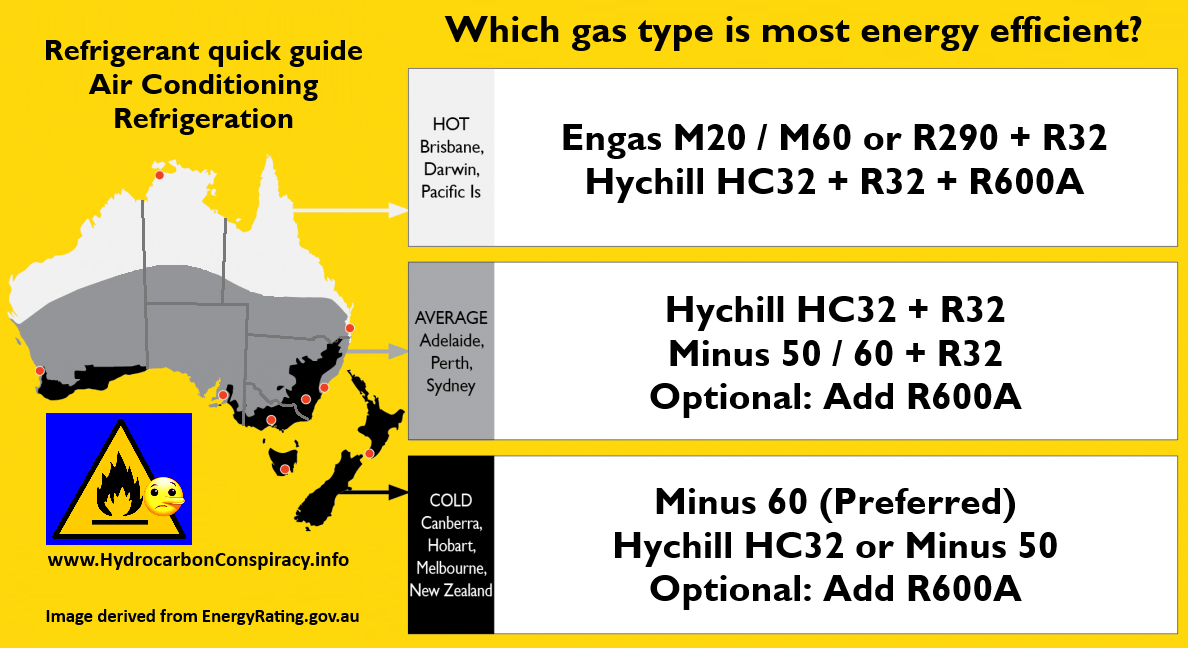

Gas is pumped into the condenser coil and is restricted by the metering device. This restriction banks up the gas in the condenser coil, causing it to heat up, and the gas that does make its way through to the evaporator coil cools down as it discharges. Different gases perform differently, and mixing gases also affects performance. Lower pressure gases (especially hydrocarbon gases) take less energy to compress - resulting in energy savings.